Calibration Services – Accuracy You Can Trust, Compliance You Can Rely On

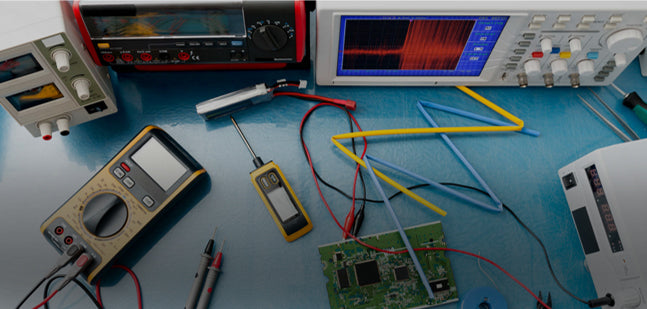

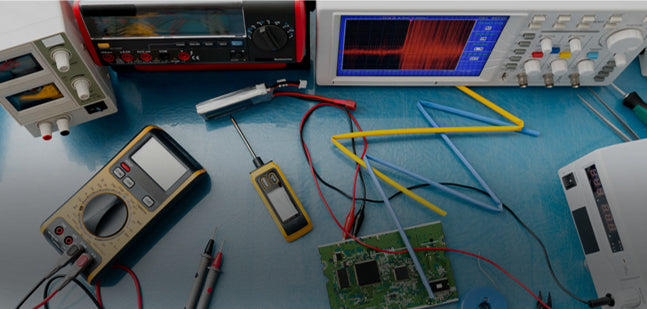

We provide Instrument calibration and laser calibration services using a computerised closed loop software-based system to eliminate human error.

OUR PROUD

RANGE OF PRODUCTS

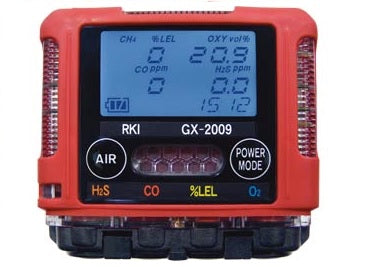

And many more… Please check our Product Category for our range of products. All our products are supported with Manufacturer’s warranty Our calibration laboratory is fully equipped to calibrate all our products. We can supply HT Italia Instruments, Wika, Dwyer, Micro, RKI, CAC and Zenith products. Want to know more about our instrument calibration services?

SUSTAINABILITY

Expert Instrument Calibration Services

Zenith is an Australian company offering complete instrumentation solutions including Sales, Service, Repair, Calibration and Installation.

Zenith provides comprehensive instrument calibration services for a wide range of Instruments in various fields such as Manufacturing, Engineering, Mining, Petro-chemical, Food Industry, Avionics, Medical, Laboratories, Pharmaceutical, Warehouses and many more.

At Zenith, we provide complete services to facilitate the calibration of different instruments. As specialists in the sphere of calibration and repair, we take the utmost care to ensure that your equipment and tools are calibrated to adhere to the highest standards. Our calibration experts have wide-reaching experience, and you can count on us for maintaining instrument compliance. For all your requirements for calibration in Australia, look no further. We take pride in our commitment to quality with a quick turnaround time. Whether you require in-house or on-site calibration, you can count on our expertise to get the job done right.

TOP SELLERS

-

GX-6000 Gas Monitor

Regular price $5,395.50 AUDRegular priceUnit price per -

Beacon 800

Regular price $4,942.91 AUDRegular priceUnit price per -

Beacon 410A

Regular price $5,226.98 AUDRegular priceUnit price per -

Beacon 200

Regular price $4,687.10 AUDRegular priceUnit price per -

Beacon 110

Regular price $2,166.00 AUDRegular priceUnit price per

-

20 188

20 188

Jobs in the Lab -

76 291

76 291

Equipment Calibrated

in the Lab -

9 386

9 386

Jobs On-site -

68 796

68 796

Equipment Calibrated

On-site -

6 956

6 956

Number of Satisfied

Customers

BLOG POSTS

OUR FAQ

Why should I calibrate a new instrument that came directly from the factory?

Sometimes new instrument calibration service will be a part of legal compliance and at other times you will need to do changes in the instrument over time. In such cases, you will need to track calibration data from the time of the initial purchase.

Why are calibration services important?

Inaccurate equipment can result in the acceptance of incorrect results. A seemingly insignificant error may be magnified into something much larger down the line. Neglecting calibration can cause direct economic losses, production downtime, quality problems and product recalls. Employee and customer safety may become at risk.

Getting a test equipment calibrated reduces costs and enhances efficiency in operations. It increases a company’s reputation for quality and safety, and will fulfil any regulatory or contractual obligations.

How often should I re-calibrate my instrument?

We suggest that you maintain a calibration history from day one and re-calibrate once a year. This enables you to compare your measurement results over time. However it depends on the application and users requirements.

What is the difference between accredited and traceable calibration?

Accredited Calibration involves approval from national and international bodies, such as the NATA, Traceable calibration is performed according to these same standards, and ensures that calibration results are correct, but an official governing body does not explicitly approve the results. However traceability of the master standard used will be provided.

What is a calibration certificate?

A calibration certificate consists of details such as what was calibrated, who performed the calibration, when and where the calibration was performed and how it was performed. The results shown on a calibration certificate are only valid at the time of calibration.

Can calibration be done on-site?

Yes, we can provide On-site calibration

service and our trained engineers can help reduce downtime.

What is required for a calibration laboratory in order to achieve accreditation?

A detailed quality policy will be needed that fulfils the requirements of ISO 17025, including the ambient conditions of the physical premises, methodology, procedures, traceability, technical skills, and record documents.

How are instruments calibrated?

Instrument calibration is a process that is done by using an existing value, known as a calibrator. The process involves using the instrument to create a measurement and comparing said measurement with the standard calibrator. The result establishes the relationship between the calibrators measurement technique and that of the instrument.

What is the purpose of the calibration of instruments?

There are two primary objectives to instrument calibration. The first is to determine the accuracy of the instrument itself. The second is to determine the traceability of the measurement, allowing one to understand and check if the device requires repair. This is why calibration of measuring instruments is extremely important.

What are the types of calibration?

There are multiple types of calibration when it comes to instrument calibration services. These include:

· Pressure calibration

· Pipette calibration

· Flow calibration

· Electrical calibration

· Temperature calibration and

· Mechanical calibration

At Zenith Instruments, we provide each of these services for calibration in Australia.